Iron and Steel

1 Introduction - Loads and Stresses

The principles of structural mechanics form the basis

for structural calculations, no matter what the materials and systems

employed. A few of the principles are set out below - the terms we have

used are those which were familiar to engineers working during the mid

19th and early part of the 20th centuries. Remember that in the very

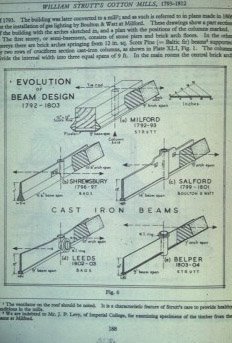

early days of iron column and beam design (1790s to 1830s) much of this

was new and engineers experimented by trial and error. The design of

columns and beams changed from project to project as engineers learnt

from their mistakes, built on their successes, developed new ideas and

discovered what other designers were doing (patents were often taken out

to try and prevent this). This section explains:

This section is not meant to be a detailed explanation of structural principles but a very brief introduction to some of the problems faced by Georgian and Victorian engineers. It's mostly based on late Victorian textbooks and partly on Modern Practical Building by Harry Bryant Newbold; first published in 1934 by Caxton. Specific aspects of the design and sizing of early steel beams can be found in the Section on Steel Frames - Early 20th century. The image on the right (regrettably the source is unknown) shows the development of William Strutt's beam designs for fireproof floors. Unfortunately, as yet, we don't have a larger image of this. |

|

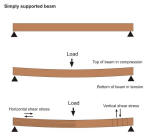

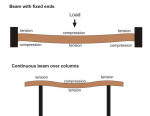

| The combined weight of roofs, floors, walls etc are called dead loads. These loads do not change once the building is complete. Dead loads can be calculated from the known weights per unit of area or volume for the various materials used. The weight of furniture, machinery, equipment and the people inside a building make up the live loads. These loads can vary in position and quantity. Live loads are not usually calculated but based on standard tables which provide figures for different types of building; offices, shops, schools, houses etc. The dead and live loads produce stresses in the building structure. During the period we are concerned with in this topic (roughly late 18th to early 19th centuries) stress was defined as the load per unit cross sectional area and as calculated in tons per square inch. Much of this topic is about the evolution of commercial buildings and much of it relies on extracts from contemporary books and catalogues. We have, therefore, decided to leave the Imperial units unaltered - converting them all to metric units would be a fairly tedious exercise with little benefit to the reader. | |

| Compressive stress: the load bearing downwards on the vertical axis

of a column - this tends to crush the fibres which make up the column.

Columns constructed in traditional materials such as stone and brick

tend to be of large cross-sectional size relative to their length. A

column in cast iron can be much more slender due to cast iron's high

compressive strength. Tensile stress: a load suspended at the end of wire produces tensile stress - it tends to tear apart the fibres. Shear stress: if two opposite forces act on a material and they are not quite in line the fibres can fail by a sliding action. A material cut by scissors is a simple example of shear failure. |

|

except where acknowledged