![]()

1 The Beginnings of the Tradition

2 The Development of the ‘Framed Wall’

3 From Trees to Timber

4 Timber Frame Types

5 Construction Elements

England and Wales have a fine inheritance of vernacular timber architecture. The majority of timber framed buildings were not originally prestigious but they have become more precious as they have become rarer. Framed structures are easy to put up and therefore easy to remove. It is the process of alteration and rebuilding, in response to changing need and fashion, rather than the false but generally held perception that timber is a relatively short lived material that is responsible for the diminished stock of historic timber buildings in England and Wales.

For thousands of years indigenous timber species provided the main source of structural material for building. During this time a management system developed for trees and woodland which provided society with a renewable and sustainable supply of timber and woodland products. The greatest period of timber building in England and Wales was between 1200 AD and 1700 AD, a period which saw the development of a sophisticated prefabricated building system which provided the majority of buildings throughout the cities, towns and villages.

The growth cycle of the indigenous broad-leaf trees of Northern Europe is such that once the root stock has become established, if the tree is felled, it will rapidly regenerate growth above ground, sending up a series of shoots, known as ‘spring’, as opposed to the original single stem. It is known that some root stocks have lasted for 1000 years, regularly being cut and re-growing thus providing a continuous renewable crop of wood. This process of management is known as coppicing. The expertise lay in selecting which shoots should be allowed to grow-on to produce usable timber for construction (Standards) and which could be allowed to grow for a limited period to provide fuel and other woodland products. Medieval carpenters were supplied with timber from a commercially managed woodland economy that was already ancient.

Many of the sophisticated planning and building techniques which the Romans introduced to England were abandoned rapidly after their departure in 410 AD. The Saxons, who gradually displaced the Britons to the western extremities of England and Wales after the Romans left, were timber builders rather than masons.

There is little evidence of a significant change in either the structural or jointing carpentry techniques immediately following the Norman conquest. One of the main reasons we are only allowed glimpses of the sophistication of the craft of carpentry pre 1200 is that builders retained the archaic means of fixing and stabilising their timber structures by sinking the posts into the ground or a continuous series of logs into a trench. While these ‘earth-fast’ systems provided a stable structure, it was at the cost of their longevity.

Currently, the earliest evidence of significant constructional change, is from around 1210 when a building in Cheddar was rebuilt with its posts set onto stone pads rather than set into the ground. This change was to revolutionise timber building. This development rapidly led to framing where posts were jointed into a cill beam which was raised above the damp ground on a plinth wall - this arrangement became known as the ‘framed wall’. It provided buildings of far greater longevity but also required a higher level of technical competence.

Improved understanding of geometry allowed carpenters to accurately set out buildings away from the site where they were to be erected. This also demanded greater design skills and care in manufacture and encouraged the increased use of joints which were structurally efficient and allowed for partial sequential test-assembly and dismantling in the carpenter’s yard prior to site erection.

The carpenter-designers of timber framed buildings worked on a practical basis, resolving structural problems as they arose. There was no recourse to theoretical calculation, any measurement was based on proportion and made use of the recently improved knowledge of geometry. Problems were solved through a combination of experience (including experience of failure) and knowledge passed from generation to generation. Timber frames structures are weakest when either the jointing arrangements or an individual component was subject to tensile force, (i.e. either the joints themselves being pulled apart or the bending action in any given timber member which induced the fibres of the wood to be excessively stretched, twisted and fail). Most of the components in timber framed buildings are therefore designed to act in compression. Where there was little choice but to have a member subject to bending and thus tensile forces, carpenters devised means by which that member could be propped to reduce and counteract the tension.

Jointing the posts on a cill beam rather than setting them into the ground removed much of the buttressing support both along and across the building. The provision of triangular bracing was the principle means by which the carpenters avoided racking within frames. Braces stiffen the frame. They help keep the frames plumb, level and square and are found in each frame element i.e. cross frames, roof frames and along wall frames. To avoid failure by buckling, braces need to be relatively short and need to be used in opposing pairs as structurally they operate in one direction only.

The predominant timber species used for structural purposes in England and Wales was oak. This is an immensely strong, durable and long grained timber. Elm, sweet chestnut, hornbeam and other timbers were also used. Typically timbers were used unseasoned, shortly after felling. ‘Green’ Oak and other timbers were considerably easier to work and joint than seasoned timber and given the typical cross sections air seasoning would have been impractical.

Foresters and carpenters had an intrinsic understanding of the nature of trees and timber they used. The most prized part of the trunk was the inner section of timber known as the heartwood. This contains the densest and most durable timber. The outer section of the trunks, the bark and sapwood have the dual purpose of protecting the heartwood and more importantly distributing food and water necessary for growth. The sapwood is the point at which an additional growth layer occurs each year, it is far less dense than the heartwood and it also contains a much higher level of sugars and moisture, making it far more susceptible to insect attack and fungal decay.

Medieval carpenters selected the smallest tree necessary for the job. There were three methods for the conversion of logs to useable timber; sawing, hewing and riving. Sawing was undertaken with a two handled saw with the trunk laid on trestles (see sawing and vertical sawing) or over a pit. The straight lines for marking out the saw cuts on the irregular logs were made using a chalked string line stretched taut, providing a relatively straight and plane surface. Hewing uses a variety of specialist axes including adzes to produce a straight, plane and frequently squared surface on irregular logs. In common with the marking of logs for sawing, chalklines provided the guide lines for true surfaces. A high proportion of the timbers in medieval buildings were riven. That is they were split along the grain. This was a much less reliable method of producing timbers of a predetermined size as the logs would split along the grain at the point of natural weakness. Riving produced timbers which were relatively strong. Unlike sawn timber the full length of the grain was intact and had not been cut through as would be the case if it had been sawn.

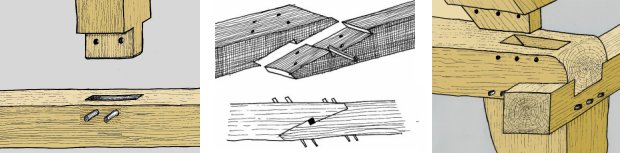

Carpenters developed complex new joints and assemblies for dealing with new structural problems although some of the pre 1200 joints continued to be used. The mortice and tenon (known to have been used for thousands of years - and shown on the left in the graphic below) gradually replaced the simpler and even more ancient lap joint as the most common joint throughout timber framing. In common with most timber framing joints, mortice and tenons were secured by timber pegs when the final erection of the building occurred. Using a system known as draw boring the hole for the peg in the sides of the mortice was slightly off-set on the tenon so that when the peg was finally driven through, the whole joint tightened up. Pegs provide considerable resistance to withdrawal but over stressing could, and did, cause failure. Improvements in their understanding of geometry enabled carpenters to develop complex lengthening joints known as scarf joints (middle below). Using these joints the carpenters were able to provide timbers longer than those which were naturally available. The right hand graphic shows the complex joint where a post meets the wall plate, tie beam and roof structure.

It is possible to divide timber framed buildings into four building types

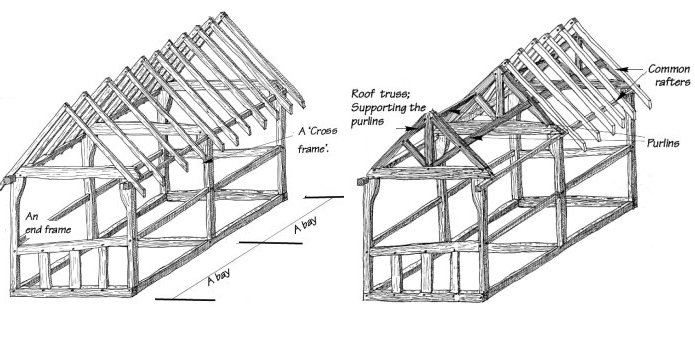

Box Frame (below left) construction consists of wall frames connected at bay intervals by cross tie beams. The roof is a separate structural element which bears onto the external walls, the roof acting as a lid on a box. Box frames have rafter roofs with no purlins supporting the rafter at mid span. Although the tie beams helped to avoid the weight of the roof spreading the walls outward, collars were added to the pairs of rafters to lessen the spreading action of the roof.

Post and Truss (below right) is by far the most common surviving timber framed building form. This form makes use of the purlin roof. Roof and wall elements are structurally united within each cross frame. The cross frames include tie beams, as they do in box-framed construction. The important difference in post and truss construction is that principal rafters are jointed into the tie beam and this forms roof trusses to carry purlins which in turn support the rafters and roof covering.

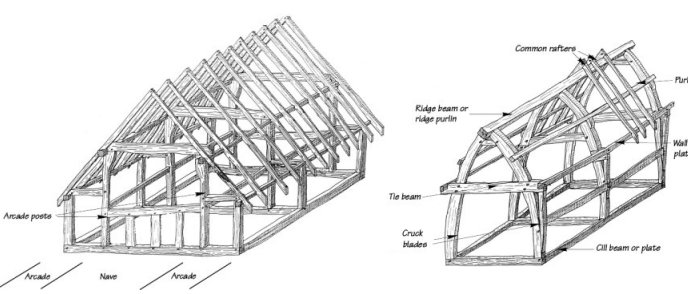

Aisled construction (below left) provides additional internal space by dividing the structure into a central nave and two side aisles. Wall posts become internal, arcade posts, and the aisles are roofed over with lean-to roofs at an angle matching the main roof.

Cruck construction (below right) is one form which seems to rouse the most interest in enthusiasts because of their simple architectural and sculptural quality. Crucks are cross frames made up of pairs of inclined timbers, most frequently book matched halves of the same tree, which meet at the apex and are tied together by some form of collar. Typically this ‘A’ frame supports the purlins (normally trenched onto the cruck blade) and the wall plates (frequently supported by the cruck’s collar). Thus, crucks transfer the load of the roof to the ground. This means the external walls are not necessarily structurally significant and frequently act simply as an enclosure.

Upper floors in timber framed buildings were relatively rare until the 1400s. Where floor spans were relatively short the structure was simply created using joists, however the typical span for the majority of floors necessitated the use of additional support for the joists and these were frequently jointed into more substantial bridging or summer beams which divided the span.

Plastered ceilings were rare in all classes of building until the 1600s. This meant that the floor structure was exposed and where these were contained within rooms occupied by the owners, ornate treatment of the beams and joists was common.

The majority of timber framed buildings were built with externally exposed timber frames. The most common form of enclosure was applied between the exposed timbers of the frame and is known as wattle and daub. It consisted of vertical timbers or staves fixed between two horizontal members of the timber frame, which supported timber laths woven between them. This element is the wattle. It supported the daub which was a rough lime-based plaster (containing animal hair, dung and locally found aggregates) which was trowelled onto the wattle and finished flush with the external face of the timber frame. The most common treatment following the application of wattle and daub was to limewash both the panels and the frame. This was commonly regularly re-applied (in some cases annually) and acted as a waterproofer, a filler of shrinkage gaps between the timber frame and wattle and daub panels, an insecticide and a decorative coating. Evidence suggests that the lime wash was the most common finish for all timber frames. It was usually coloured using locally available materials, coloured soil, blood and other materials. The ‘black and white’ treatment of timber frames is largely a Victorian fashion.

Window frames and door frames were incorporated into the timber frame itself rather than separate components as is the case nowadays. The glazing of windows became increasingly common in the early 1600s; until then most windows were open to the elements with protection being provided by sliding or hinged internal, or external, shutters.

©2008 University of the West of England, Bristol

except where acknowledged